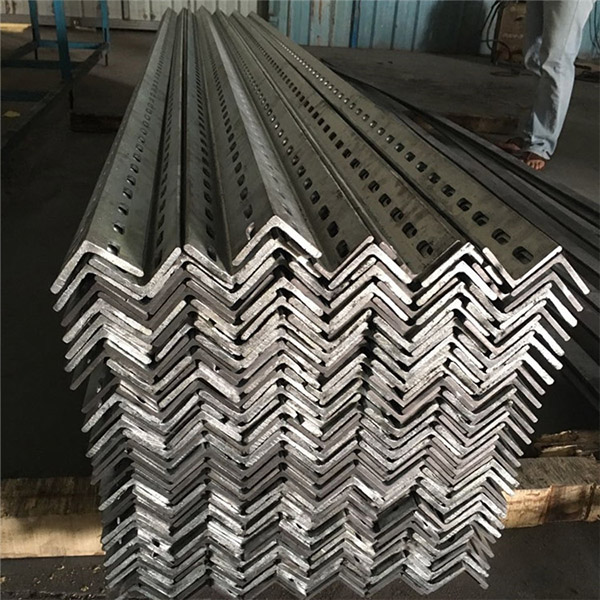

Jis -G3192 Azzar Angolu tal-Kostruzzjoni Galvanizzat Hot Rolled

Standards: Ace, ASTM, DIN, GB, JIS

Grad: Q195-Q420 serje

Post ta 'Oriġini: Tianjin, iċ-Ċina

Isem tad-Ditta: Jinbaicheng

Mudell: Q195, Q235, Q345

Tip: Ugwali

Applikazzjoni: Struttura tal-bini

Tolleranza: ± 5%

Servizz ta 'proċessar: Qtugħ

Isem tal-prodott: JIS -G3192 hot rolled galvanizzat angolu azzar kostruzzjoni

Teknoloġija: Hot Rolling

Trattament tal-wiċċ: galvanizzat bis-sħana

Forma: Ugwaljanza, inugwaljanza

Wiċċ: azzar b'karbonju baxx sempliċi

Materjal: Q195-Q235

Oġġett: Ħadid tal-angolu tal-azzar tal-karbonju iswed

Tul: 6m-12m

Hot-dip galvanizzat angolu proċess ta 'l-azzar: azzar angolu pickling-ilma ħasil-dippjar jgħinu kisi solvent-tnixxif preheating-rack kisi-tkessiħ-passivazzjoni-tindif-illustrar-hot-dip galvanizzar mitmuma. Il-ħxuna tas-saff galvanizzat ta 'l-azzar angolu galvanizzat hot-dip hija uniformi, sa 30-50um, u l-affidabilità hija tajba. Is-saff galvanizzat u l-azzar huma magħqudin b'mod metallurġiku u jsiru parti mill-wiċċ tal-azzar. Għalhekk, id-durabilità tal-kisi tal-azzar tal-angolu galvanizzat hot-dip hija aktar affidabbli. .

1. Spiża baxxa tal-ipproċessar: l-ispiża tal-galvanizzar bis-sħana u l-prevenzjoni tas-sadid hija aktar baxxa minn dik ta 'kisjiet oħra taż-żebgħa;

2. Durabbli u durabbli: L-azzar ta 'angolu galvanizzat hot-dip għandu l-karatteristiċi ta' tleqqija tal-wiċċ, saff taż-żingu uniformi, l-ebda kisi ta 'tnixxija, l-ebda taqtir, adeżjoni qawwija, u reżistenza qawwija għall-korrużjoni. Fl-ambjent suburbani, il-ħxuna standard tal-galvanizzar bis-sħana kontra s-sadid tista 'tinżamm Aktar minn 50 sena mingħajr tiswija; f'żoni urbani jew żoni offshore, is-saff standard ta 'kontra l-korrużjoni galvanizzat hot-dip jista' jinżamm għal 20 sena mingħajr tiswija;

3. Affidabilità tajba: Is-saff galvanizzat u l-azzar huma magħqudin b'mod metallurġiku u jsiru parti mill-wiċċ tal-azzar, għalhekk id-durabilità tal-kisi hija aktar affidabbli;

4. Il-kisja għandha toughness qawwija: il-kisja taż-żingu tifforma struttura metallurġika speċjali, li tista 'tiflaħ ħsara mekkanika waqt it-trasport u l-użu;

5. Protezzjoni komprensiva: kull parti tal-partijiet miksija tista 'tiġi miksija biż-żingu, anke f'daħliet, kantunieri li jaqtgħu u postijiet moħbija jistgħu jiġu protetti bis-sħiħ;

6. Iffrankar ta 'ħin u iffrankar tax-xogħol: il-proċess ta' galvanizzazzjoni huwa aktar mgħaġġel minn metodi oħra ta 'kostruzzjoni tal-kisi, u jista' jevita l-ħin meħtieġ għaż-żebgħa fuq is-sit tal-kostruzzjoni wara l-installazzjoni.

Huwa użat ħafna f'torrijiet tal-enerġija elettrika, torrijiet tal-komunikazzjoni, ferroviji, protezzjoni tal-awtostradi, arbli tal-lampi tat-toroq, komponenti tal-baħar, komponenti strutturali tal-azzar tal-bini, faċilitajiet anċillari ta 'substation, industrija ħafifa, eċċ.

Tabella tal-piż tal-azzar tal-angolu galvanizzat hot-dip

| Numru ta 'l-Azzar ta' l-Angolu | Daqs/mm | Piż teoretiku (kg/m) | Manifattur | Numru ta 'l-Azzar ta' l-Angolu | Daqs/mm | Piż teoretiku (kg/m) | Manifattur | ||||

|

| a | d | r |

|

|

| a | d | r |

|

|

| 2 | 20 | 3 | 3.5 | 0.889 |

| 10 | 100 | 12 | 12 | 17.898 |

|

| 2 | 20 | 4 | 3.5 | 1.145 |

| 10 | 100 | 14 | 12 | 20.611 |

|

| 2.5 | 25 | 3 | 3.5 | 1.124 |

| 10 | 100 | 16 | 12 | 23.257 |

|

| 2.5 | 25 | 4 | 3.5 | 1.459 |

| 11 | 110 | 7 | 12 | 11.928 |

|

| 3 | 30 | 3 | 4.5 | 1.373 |

| 11 | 110 | 8 | 12 | 13.532 |

|

| 3 | 30 | 4 | 4.5 | 1.786 |

| 11 | 110 | 10 | 12 | 16.69 |

|

| 3.6 | 36 | 3 | 4.5 | 1.656 |

| 11 | 110 | 12 | 12 | 19.782 |

|

| 3.6 | 36 | 4 | 4.5 | 2.163 |

| 11 | 110 | 14 | 12 | 22.809 |

|

| 3.6 | 36 | 5 | 4.5 | 2.654 |

| 12.5 | 125 | 8 | 14 | 15.504 |

|

| 4 | 40 | 3 | 5 | 1.852 |

| 12.5 | 125 | 10 | 14 | 19.133 |

|

| 4 | 40 | 4 | 5 | 2.422 |

| 12.5 | 125 | 12 | 14 | 22.696 |

|

| 4 | 40 | 5 | 5 | 2.976 |

| 12.5 | 125 | 14 | 14 | 26.193 |

|

| 4.5 | 45 | 3 | 5 | 2.088 |

| 14 | 140 | 10 | 14 | 21.488 |

|

| 4.5 | 45 | 4 | 5 | 2.736 |

| 14 | 140 | 12 | 14 | 25.522 |

|

| 4.5 | 45 | 5 | 5 | 3.369 |

| 14 | 140 | 14 | 14 | 29.49 |

|

| 4.5 | 45 | 6 | 5 | 3.985 |

| 14 | 140 | 16 | 14 | 33.393 |

|

| 5 | 50 | 3 | 5.5 | 2.332 |

| 16 | 160 | 10 | 16 | 24.729 |

|

| 5 | 50 | 4 | 5.5 | 3.059 |

| 16 | 160 | 12 | 16 | 29.391 |

|

| 5 | 50 | 5 | 5.5 | 3.77 |

| 16 | 160 | 14 | 16 | 33.987 |

|

| 5 | 50 | 6 | 5.5 | 4.465 |

| 16 | 160 | 16 | 16 | 38.518 |

|

| 5.6 | 56 | 3 | 6 | 2.624 |

| 18 | 180 | 12 | 16 | 33.159 |

|

| 5.6 | 56 | 4 | 6 | 3.446 |

| 18 | 180 | 14 | 16 | 38.383 |

|

| 5.6 | 56 | 5 | 6 | 4.251 |

| 18 | 180 | 16 | 16 | 43.542 |

|

| 5.6 | 56 | 8 | 6 | 6.568 |

| 18 | 180 | 18 | 16 | 48.634 |

|

| 6.3 | 63 | 4 | 7 | 3.907 |

| 20 | 200 | 14 | 18 | 42.894 |

|

| 6.3 | 63 | 5 | 7 | 4.822 |

| 20 | 200 | 16 | 18 | 48.68 |

|

| 6.3 | 63 | 6 | 7 | 5.721 |

| 20 | 200 | 18 | 18 | 54.401 |

|

| 6.3 | 63 | 8 | 7 | 7.469 |

| 20 | 200 | 20 | 18 | 60.056 |

|

| 6.3 | 63 | 10 | 7 | 15.1 |

| 20 | 200 | 24 | 18 | 71.168 |

|

| 7 | 70 | 4 | 8 | 4.372 |

|

|

|

|

|

|

|

| 7 | 70 | 5 | 8 | 5.397 |

|

|

|

|

|

|

|

| 7 | 70 | 6 | 8 | 6.406 |

|

|

|

|

|

|

|

| 7 | 70 | 7 | 8 | 7.398 |

|

|

|

|

|

|

|

| 7 | 70 | 8 | 8 | 8.373 |

|

|

|

|

|

|

|

| 7.5 | 75 | 5 | 9 | 5.818 |

|

|

|

|

|

|

|

| 7.5 | 75 | 6 | 9 | 6.905 |

|

|

|

|

|

|

|

| 7.5 | 75 | 7 | 9 | 7.976 |

|

|

|

|

|

|

|

| 7.5 | 75 | 8 | 9 | 9.03 |

|

|

|

|

|

|

|

| 7.5 | 75 | 10 | 9 | 11.089 |

|

|

|

|

|

|

|

| 8 | 80 | 5 | 9 | 6.211 |

|

|

|

|

|

|

|

| 8 | 80 | 6 | 9 | 7.376 |

|

|

|

|

|

|

|

| 8 | 80 | 7 | 9 | 8.525 |

|

|

|

|

|

|

|

| 8 | 80 | 8 | 9 | 9.658 |

|

|

|

|

|

|

|

| 8 | 80 | 10 | 9 | 11.874 |

|

|

|

|

|

|

|

| 9 | 90 | 6 | 10 | 8.35 |

|

|

|

|

|

|

|

| 9 | 90 | 7 | 10 | 9.656 |

|

|

|

|

|

|

|

| 9 | 90 | 8 | 10 | 10.946 |

|

|

|

|

|

|

|

| 9 | 90 | 10 | 10 | 13.476 |

|

|

|

|

|

|

|

| 9 | 90 | 12 | 10 | 15.94 |

|

|

|

|

|

|

|

| 10 | 100 | 6 | 12 | 9.366 |

|

|

|

|

|

|

|

| 10 | 100 | 7 | 12 | 10.83 |

|

|

|

|

|

|

|

| 10 | 100 | 8 | 12 | 12.276 |

|

|

|

|

|

|

|

| 10 | 100 | 10 | 12 | 15.12 |

|

|

|

|

|

| |

| Isem tal-prodott | Azzar tal-angolu |

| Forma | Ugwaljanza/inugwaljanza |

| Standard | Aisi, astm, bs, din, gb, jis |

| Grad | Q235/q345/ss400/st372/st52/q420/q460/s235jr/s275jr |

| Speċifikazzjoni | 20 * 20-200 * 200mm |

| Ħxuna | 6-35mm |

| Tul | 6m, 9m, 12m jew personalizzati |

| Trattament tal-wiċċ | Hot dip galvanizzat / iswed / miżbugħa |

| Kisi taż-żingu | 30-90um |

| Pakkett | Għaqda |

| Ħin tal-kunsinna | 10-20 jum |

| Termini tal-ħlas | L/c, t/t jew unjoni tal-punent |